9007 BSPP to NPTF Fittings – The Complete Guide

In the world of plumbing and hydraulic systems, choosing the right fitting is crucial for ensuring safe, efficient, and leak-proof connections. One of the most common conversions involves British Standard Pipe Parallel (BSPP) fittings to National Pipe Tapered Fuel (NPTF) fittings.

In this comprehensive guide, we will explore everything you need to know about the 9007 BSPP to NPTF fitting, including its applications, benefits, specifications, and much more. By the end of this article, you will be well-equipped to make informed decisions regarding your plumbing and hydraulic projects.

Introduction

The 9007 BSPP to NPTF fitting is an essential component in many hydraulic systems, especially when dealing with different international standards. Understanding the nuances of these fittings can greatly impact the efficiency and reliability of your systems.

This guide aims to provide comprehensive insights and practical advice to ensure that you have the information needed to choose and utilize these fittings effectively.

Understanding BSPP and NPTF Fittings

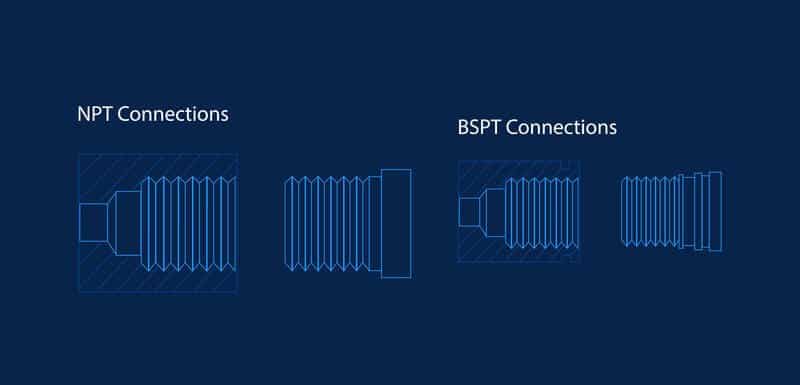

What is BSPP?

British Standard Pipe Parallel 9007 BSPP to NPTF Fittings are used extensively in plumbing and hydraulic applications. They feature a parallel thread design, which means that the threads do not taper; they remain the same diameter throughout their length. This design allows for the use of O-rings or seals to create a tight and leak-proof joint.

Key Characteristics of BSPP:

- Thread Type: Parallel threads.

- Sealing Mechanism: Utilizes O-rings or flat seals.

- Application: Commonly used in low-pressure applications, such as water and gas systems.

What is NPTF?

National Pipe Tapered Fuel (NPTF) fittings are designed for use in fuel and gas applications in North America. They feature a tapered thread design, which means that the diameter of the threads decreases along the length of the fitting. This design allows for a self-sealing joint when the threads are tightened.

Key Characteristics of NPTF:

- Thread Type: Tapered threads.

- Sealing Mechanism: Sealing occurs through mechanical deformation of the threads.

- Application: Widely used in high-pressure applications, such as fuel and hydraulic systems.

Why Use a 9007 BSPP to NPTF Fitting?

When working with systems that involve both British and American standards, the 9007 BSPP to NPTF fitting is essential for a few reasons:

- Compatibility: This fitting allows for the seamless integration of components that use different thread standards, enabling effective communication and flow between systems.

- Efficiency: It reduces the need for multiple adapters or conversions, streamlining the installation process and minimizing potential points of failure.

- Reliability: By using a fitting designed specifically for this conversion, you can ensure a leak-proof seal, thereby increasing the overall reliability of your hydraulic or plumbing system.

Specifications of 9007 BSPP to NPTF Fittings

To effectively use a 9007 BSPP to NPTF fitting, it’s important to understand its specifications. Here are some key attributes:

- Material: Typically made from brass, stainless steel, or other durable materials.

- Pressure Rating: Generally rated for high-pressure applications; verify with manufacturer specifications.

- Size Range: Available in various sizes to accommodate different tubing and piping requirements.

- Thread Pitch: Must be compatible with BSPP and NPTF standards for proper sealing.

Read More: Ila Kreischer – A Glimpse Into the Life of Bert Kreischer’s Daughter

Applications of 9007 BSPP to NPTF Fittings

- Hydraulic Systems: Essential for connecting different hydraulic components that utilize different thread types.

- Automotive: Commonly used in fuel and oil lines, ensuring secure connections that can withstand high pressures.

- Manufacturing: Useful in industrial applications where diverse piping systems must be integrated.

- Aerospace: Employed in fuel systems where compatibility between British and American fittings is critical.

Installation Guidelines for 9007 BSPP to NPTF Fittings

- Preparation: Clean the threads of both the 9007 BSPP to NPTF Fittings and NPTF fittings to remove any debris or old sealant.

- Thread Sealant: Apply an appropriate thread sealant to the NPTF fitting to ensure a leak-proof connection.

- Tightening: Hand-tighten the fitting and then use a wrench to tighten it further, taking care not to over-tighten, which could damage the threads.

- Testing: After installation, run a pressure test to check for leaks.

Maintenance Tips for Fittings

- Visual Inspections: Regularly check fittings for signs of wear, corrosion, or damage.

- Leak Testing: Periodically conduct leak tests to ensure the integrity of the connections.

- Cleaning: Keep fittings clean to avoid buildup that could affect performance.

- Lubrication: Apply appropriate lubricants to moving parts as necessary.

Comparison with Other Fitting Types

BSPT (British Standard Pipe Tapered)

- Thread Type: Tapered

- Sealing: Similar to NPTF but typically used in different applications.

- Use Case: More suited for British standards and systems.

NPT (National Pipe Thread)

- Thread Type: Tapered

- Sealing: Utilizes tape or paste for sealing.

- Use Case: Common in non-fuel applications.

Read More: DD Osama Age – The Life, Career, and Rise of a Young Rap Sensation

Troubleshooting Common Issues

1. Leaking Fittings

- Cause: Incorrect installation or damage to the threads.

- Solution: Reinstall with appropriate sealant or replace damaged fittings.

2. Difficulty in Tightening

- Cause: Mismatched thread types.

- Solution: Verify compatibility of fittings before installation.

3. Corrosion

- Cause: Exposure to harsh chemicals or environmental conditions.

- Solution: Use corrosion-resistant materials and regularly inspect fittings.

Conclusion

The 9007 BSPP to NPTF fitting is an essential component for ensuring seamless compatibility between British and American plumbing and hydraulic systems. By understanding the characteristics, specifications, and applications of this fitting, you can make informed decisions that enhance the efficiency and reliability of your systems. Remember to follow proper installation and maintenance practices to ensure long-lasting performance.

FAQs

What is the difference between BSPP and NPTF fittings?

9007 BSPP to NPTF Fittings feature parallel threads and use seals for leakage prevention, while NPTF fittings have tapered threads and rely on the threads for sealing.

Can I use a 9007 BSPP to NPTF fitting in high-pressure applications?

Yes, the to9007 BSPP to NPTF Fittings is designed for high-pressure systems, but always verify the manufacturer’s specifications.

What materials are commonly used for 9007 BSPP to NPTF fittings?

These 9007 BSPP to NPTF Fittings are often made from brass or stainless steel due to their durability and resistance to corrosion.

How do I ensure a leak-proof seal with a 9007 BSPP to NPTF fitting?

Apply an appropriate thread sealant and ensure that 9007 BSPP to NPTF Fittings are tightened properly without over-tightening.

Can I convert other types of fittings using a 9007 BSPP to NPTF fitting?

This fitting is specifically designed for 9007 BSPP to NPTF Fittings conversions; other conversions may require different fittings.

What are the common applications for 9007 BSPP to NPTF fittings?

These fittings are used in hydraulic systems, automotive fuel lines, manufacturing, and aerospace applications.

How often should I inspect my fittings?

Regular visual inspections should be conducted, and more thorough checks should occur during routine maintenance.

What should I do if my fitting is leaking?

Reinstall the fitting with new sealant or replace it if there are signs of damage.

Is it necessary to use thread sealant with NPTF fittings?

Yes, using thread sealant is recommended to ensure a leak-proof connection.

Where can I purchase 9007 BSPP to NPTF fittings?

These fittings are available at plumbing supply stores, online retailers, and specialized hydraulic component suppliers.

Read More: